Compression molded magnets are primarily composed of isotropic NdFeB powder and a thermosetting binder. They feature a relatively higher powder filling ratio and superior magnetic properties compared to injection molded magnets. As a result, they can serve as replacements for sintered ferrite magnets and sintered Neodymium magnets in certain applications. Unlike injection molded magnets, compression molded magnets are better suited to regular shapes and scenarios with low mechanical strength requirements. To prevent corrosion and ensure optimal performance—particularly in humid environments—compression molded magnets require an epoxy resin coating applied through electrophoresis or spraying.

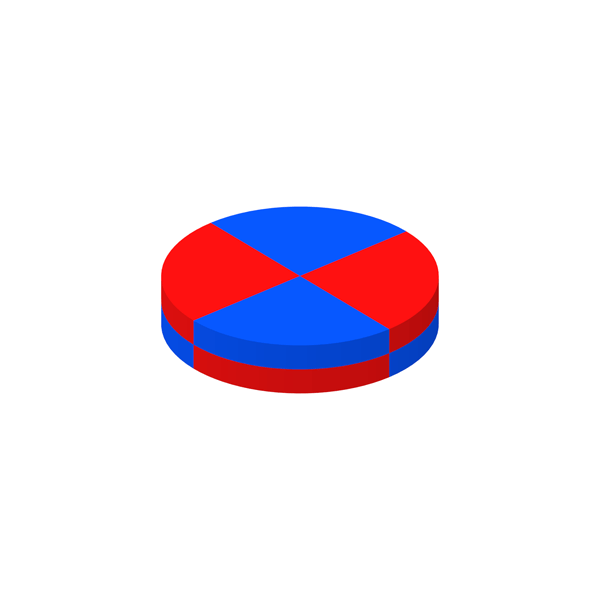

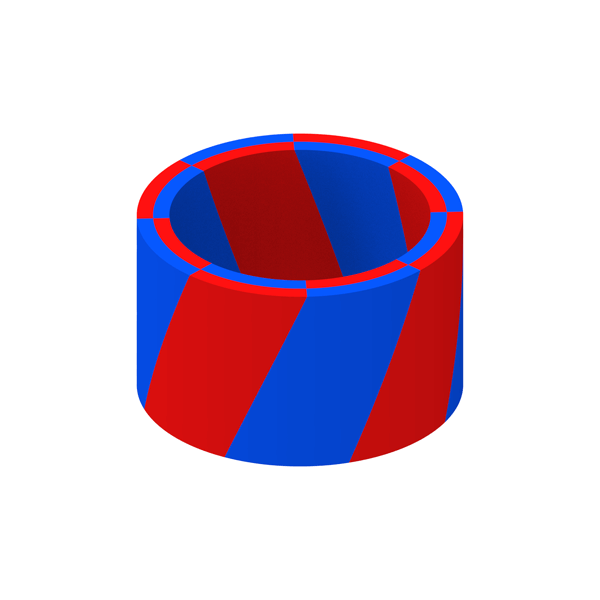

Being isotropic, these magnets can be magnetized in any direction. Over the past several decades, compression molded magnets have grown increasingly popular, mainly because the manufacturing process is well-suited for producing thin-walled ring magnets with high length-to-diameter (L/D) ratios, which are now extensively used in brushless DC motors.