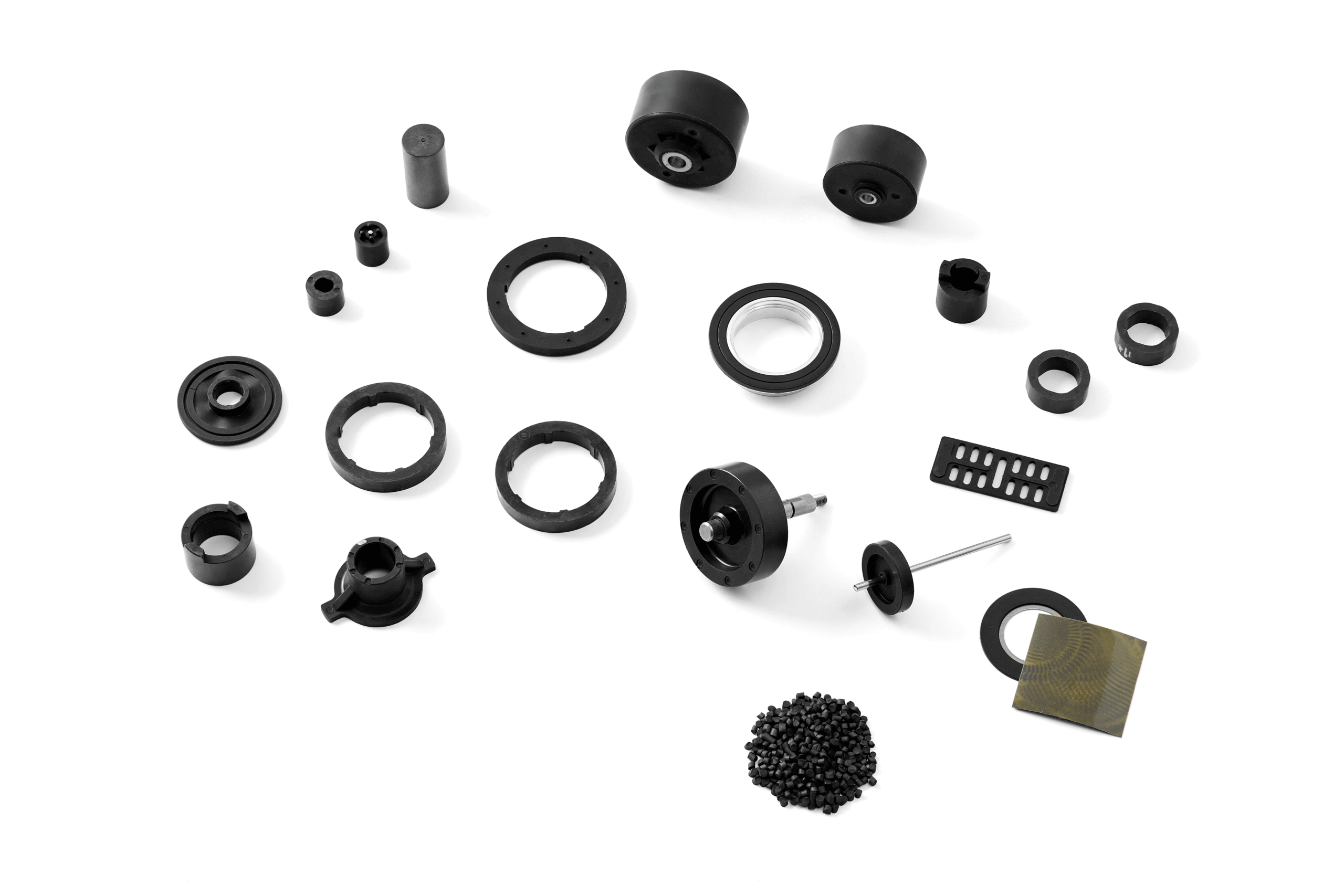

Injection ferrite magnets are a type of bonded magnet produced by embedding Strontium ferrite powder or Barium ferrite powder in a thermoplastic binder, such as PA6 (Nylon 6), PA12 (Nylon 12), or PPS (Polyphenylene Sulfide). The ratios between the ferrite magnetic powder and binder are virtually limitless, resulting in numerous grades tailored to specific needs regarding moisture absorption, magnetic properties, mechanical properties, and temperature resistance. A key advantage of the injection molding process for manufacturing these magnets is the ability to achieve a wide variety of shapes.

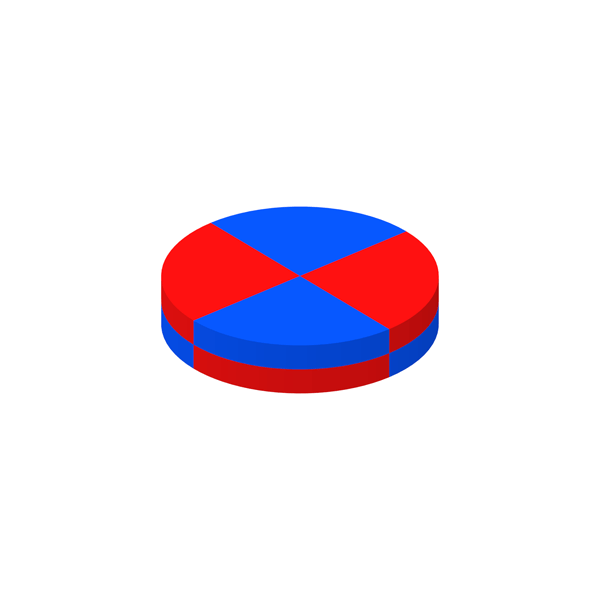

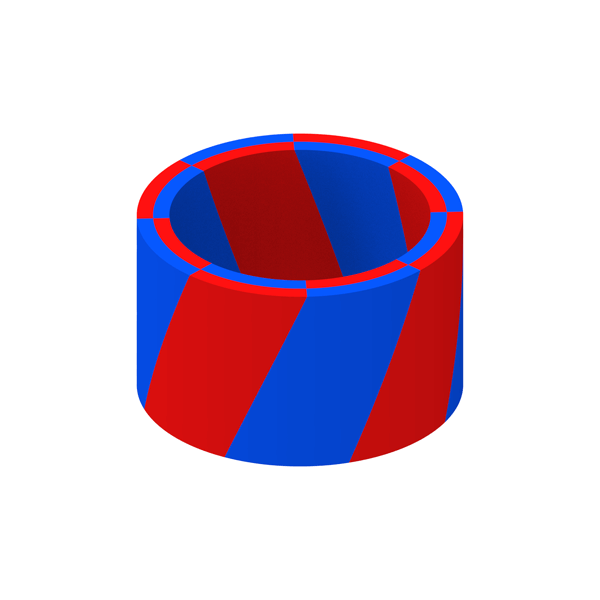

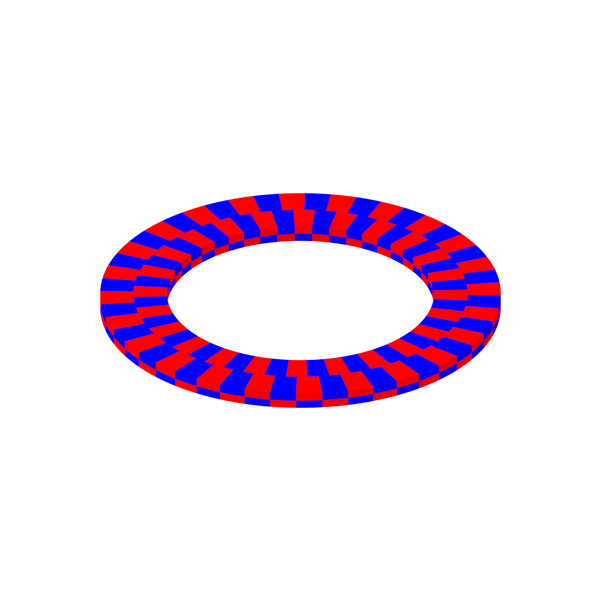

The injection molding process also enables products to be manufactured with such tight tolerances that reworking is typically unnecessary. Another benefit is the capability to mold these materials directly alongside polymer or metal components, which helps reduce subsequent assembly costs. Depending on the type of ferrite magnetic powder used, injection ferrite magnets may require magnetic orientation during the injection molding process to optimize their magnetic properties.