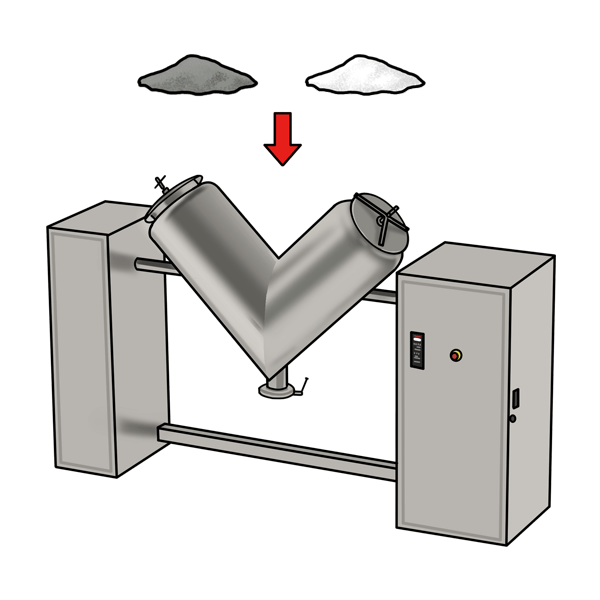

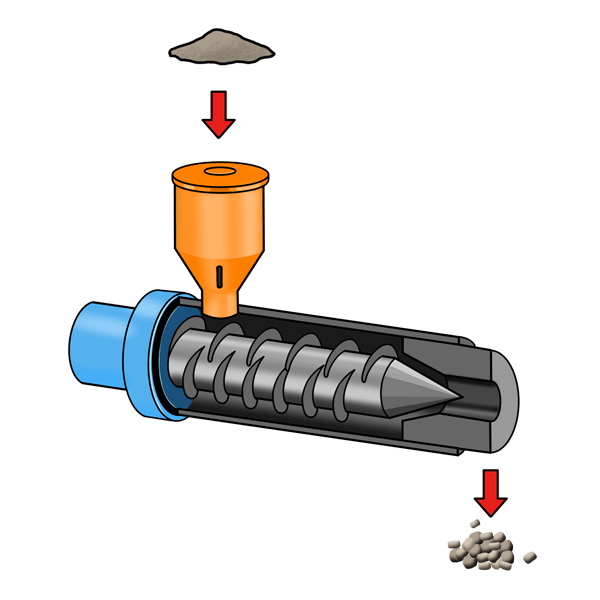

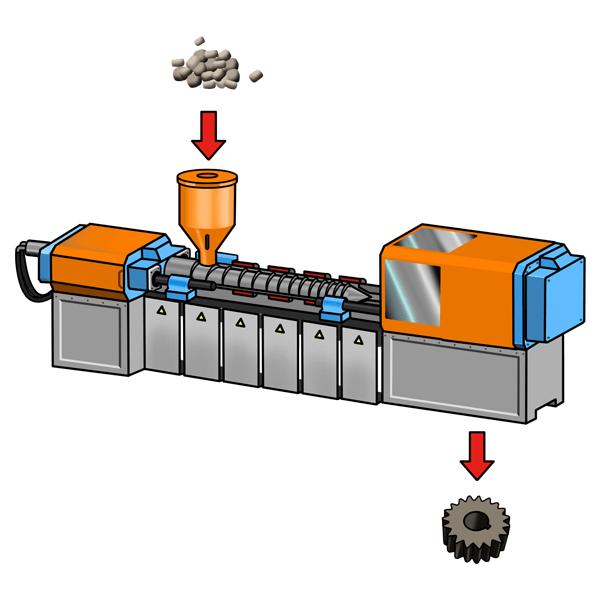

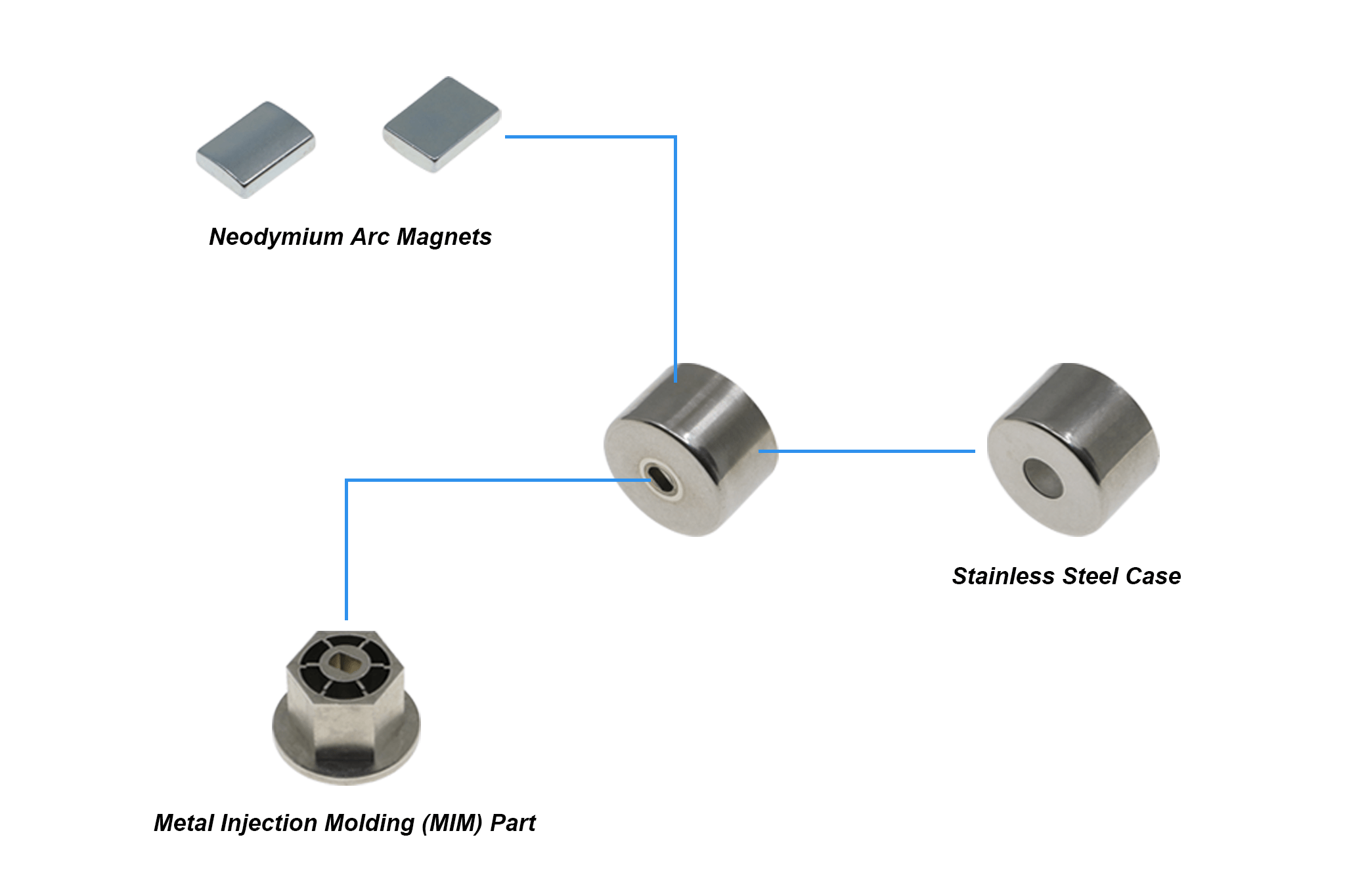

Injection molding is mainly used for making plastic parts, but it also works well for producing high volumes of detailed ceramic or metal parts. Metal injection molding (MIM) is a specialized metalworking process where finely powdered metal is mixed with a binder material, such as wax or polypropylene, to create a “feedstock.” This feedstock is then shaped and solidified using injection molding process.

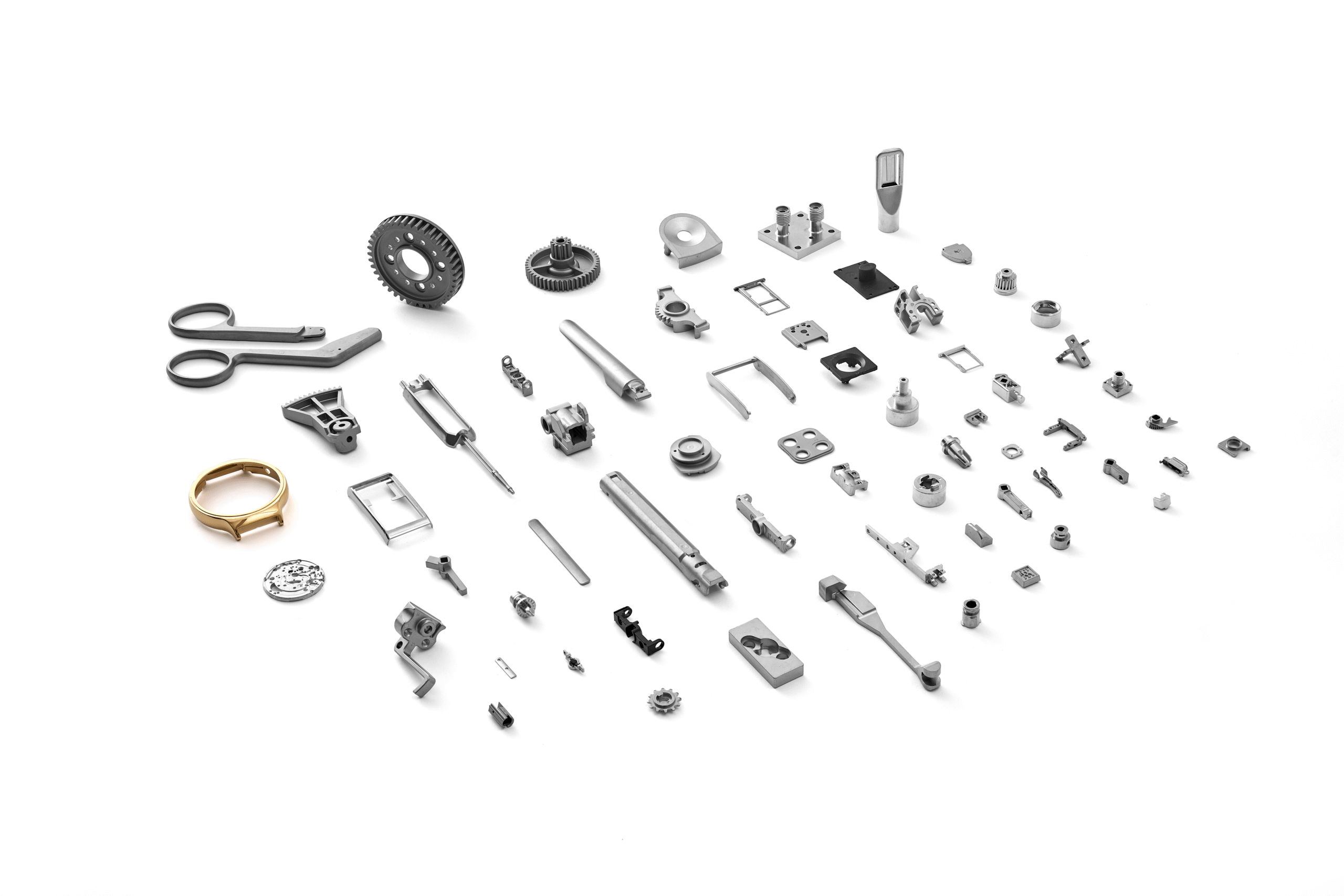

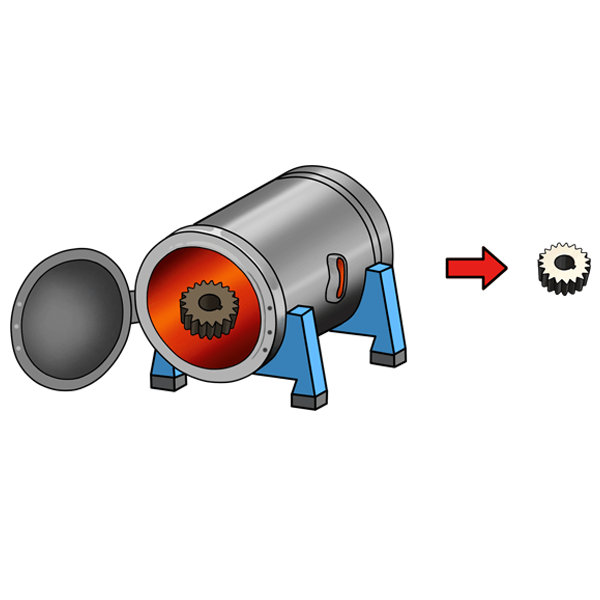

MIM combines the most useful characteristics of powder metallurgy and plastic injection molding to produce small, complex-shaped metal components with outstanding mechanical properties that are difficult to achieve with traditional machining methods. The molding process allows high-volume, intricate parts to be formed in a single step, reducing production time and costs. After molding, the parts go through debinding to remove the binder and sintering to make the powder denser. The finished products are small components used in many industries and applications, such as automotive parts, electronics, medical devices, aerospace tools, and consumer goods.